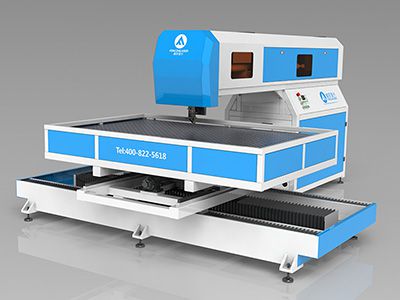

BendPro-32B – Automatic Rule Bender for Steel Rule Processing

Benderpro-32B automatic rule bender is built particularly for manufacturing laser steel rule dies used to form electronic boards, rigid boxes, carton boxes, blister packs, hang tags, stickers, wine boxes, gift boxes, leather products, etc. The automatic rule bending and processing machine features dual ballscrew feeding system and combines bending, straight cutting, lipping, bridging, broaching and nicking tools.

Technical Specifications

- Max. bend angle: 95°

- Rule height: 7-32mm

- Rule thickness: 0.45-1.07mm

- Broaching wheel: 115°, 150° (rectangle shape)

- Nicking wheel: 0.3-0.5mm width

- Min. radius to be bent 180°: R3.5

- Min. radius to be bent 90°: R1.0

- Min. bending size: 1.5mm

- Min. cutting size: 1mm

- Support format: DWG, DXF, AI

- Machine dimensions: 2000×900×1500mm

- Machine weight: 500kg

- Computer configuration: Intel I3 CPU, RAM 4GB, Windows7

- Power supply: single phase 220V, 20A, 50/60Hz, 2kW

- Air pressure: 6-8kg/cm

Options

- Perforating (tooling size 1-2mm)

- Hole punching (e.g. round hole, euro hole)

- Nicking (tooling size 0.2-1mm)

Features

- Independently developed dual ballscrew feeding and clamping unit holds the steel rule and conducts continuous feeding, significantly improving production efficiency and precision;

- Modular cutting unit is adjustable to accommodate different-height cutting materials of the same bevel height;

- One set of broaching tools, broaching depth is adjustable by software;

- Mold is made of imported high grade steel which is hardened by heat treating process, offering high strength and strong durability;

- Machine body is constructed with robust welded structure of square steel tubing, and processed utilizing gantry milling machine to ensure the high assembling precision and high stability of the machine;

- Large torque servo motor is adopted to generate high cutting force, high cutting speed and exceptional stability, enabling the blades to be assembled with seamless joints;

- Cutting and bending tools feature accurate positioning function, easy to maintenance;